Centrifuge Machine FAQ Guide: Your Ultimate Partner For Centrifugation In Laboratory

If you are in a lab, blood station, clinical laboratory, or CDC, a centrifuge machine will be the perfect piece of equipment for centrifugal separation of samples in your department. With the continuous development of technological innovations, the centrifuged effect and reproducibility of laboratory centrifuge has been improved even more. However, it is critical to address key questions about centrifugal machine applications, classifications, accessories, and more before making a selection.

Our comprehensive Centrifuge Machine FAQ Guide simplifies the process by detailing how centrifugation machine work, common problems, and best maintenance practices. It also addresses common questions such as “Centrifuge Rotor Types” and “Centrifuge Tube Types,” equipping you with the knowledge you need to make informed decisions.

Find out why centrifuge machines are the first choice for separating, purifying and concentrating samples from sample solutions. With their efficient design, low noise levels and wide range of applications, centrifuge machines in laboratory are guaranteed to meet the requirements of high-quality and precise experiments while ensuring their safety and reliability.

This guide also provides a reference for the time and speed required to separate blood and clarifies how blood centrifuge machines can be compliant and risk-free separation equipment. Whether you're launching a new experimental department or upgrading existing instrumentation, this guide has you covered.

Don't miss this important resource designed to maximize the matching of efficient laboratory centrifuges to your samples. Read the complete FAQ guide now!

What Is Centrifuge?

Lab centrifuge is an instrument that utilizes centrifugal force to separate components of different densities or particle sizes in a mixture, and it is an indispensable basic equipment in the fields of biochemistry, molecular biology, clinical medicine, pharmacy, chemical industry and so on.

What Is Centrifugal Force?

In Newtonian mechanics, centrifugal force is an inertial force (also known as “virtual force” or “pseudo-force”) that appears to act on all objects when viewed in a rotating frame of reference, and is directed away from the axis of rotation that is parallel to the axis of rotation and passes through the origin of the coordinate system.

What Is Centrifugation?

The principle of centrifuge technology is to utilize the strong centrifugal force generated when an object is rotating at high speed to cause suspended particles placed in a rotating body to settle or float, thus enabling some particles to achieve concentration or separation from other particles.

What Is The Working Principle Of Centrifuge?

Centrifuge uses are in simulating the effect of the earth's gravity field through centrifugal force, prompting objects to undergo a settling motion, thus realizing the separation of components of different densities and molecular levels in substances. The application of centrifugation separation technique is known as separation technology, which is now widely used in scientific research and production sectors, and has become one of the important instruments and equipment for modern scientific research.

What Is The Application Of a Centrifuge?

University laboratories: Centrifugal machines are often utilized for the separation and extraction of biological material samples such as cells, proteins, viruses, and DNA/RNA. It is capable of rapid cooling, precise and efficient stratification, safe and smooth.

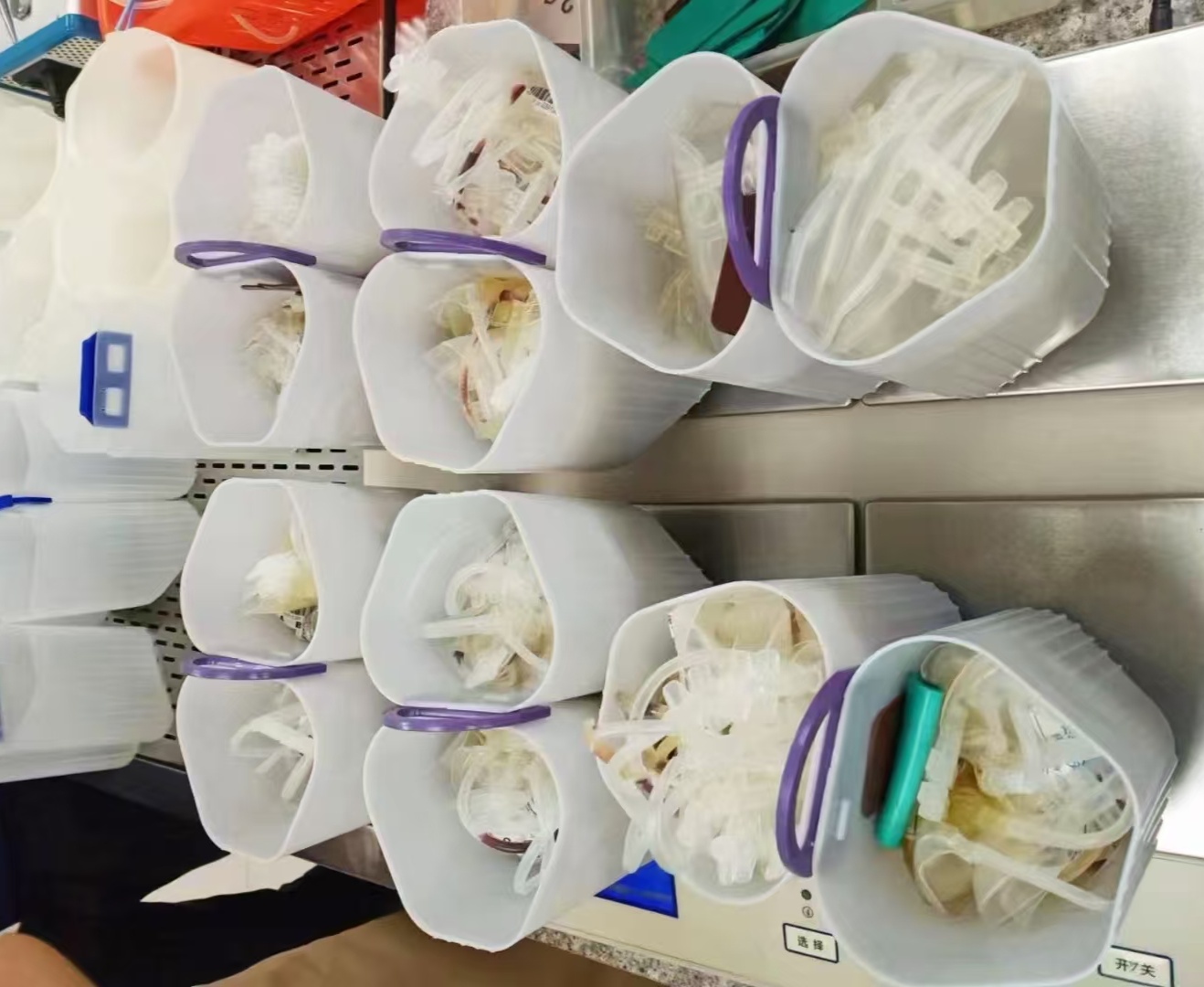

Hospital laboratory, blood transfusion department, pathology laboratory: Blood centrifuge is commonly used for separation of blood, body fluids, pathology samples. It has the advantages of large flux, multi-rotor selection, and multi-purpose.

Bio-pharmaceutical enterprises: Centrifuges are commonly used in the collection of bacterial fermentation fluid, protein precipitation and purification, and other large-capacity biological samples extraction and preparation work. It has the advantages of large capacity, fast centrifugal speed, good effect, low noise, corrosion-resistant rotor and so on.

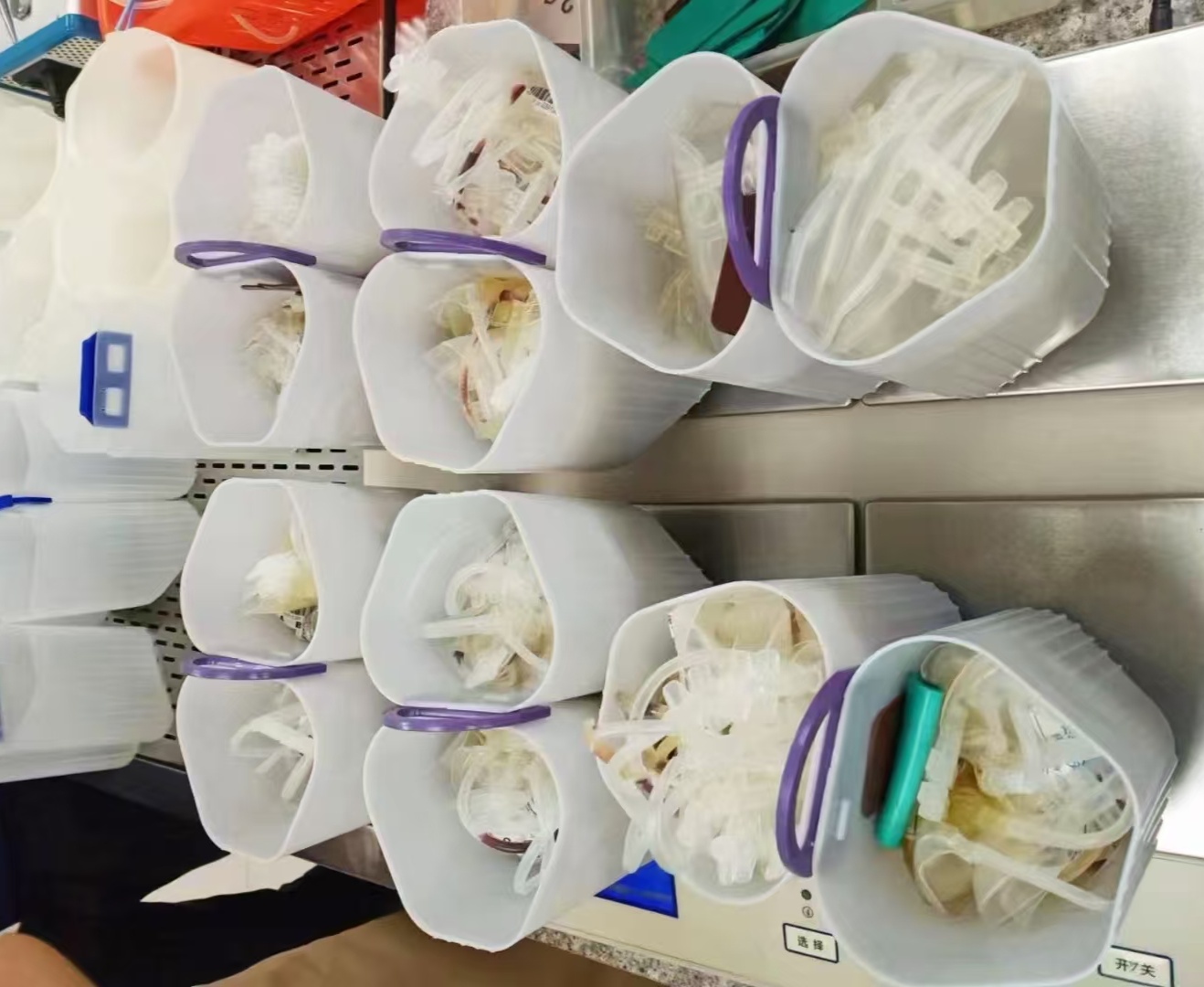

Blood station laboratory: Centrifuga are mainly used for separating blood samples and testing their safety indexes. And in the component department, it is mainly used for the separation and preparation of component blood. It has the advantages of large capacity, direct processing of blood bags, and customized display function in blood station.

CDC Laboratory Section: Clinical centrifuges are mainly used for the separation and extraction of various samples such as cells, bacteria, viruses, molds, body fluids and blood. It has the advantages of safe operation and stable operation.

What Does a Centrifuge Do?

Centrifuges lab are widely used in hospitals and laboratories for the separation of liquid mixtures of organisms, chlorophyll, protein nucleic acids and other liquids. Centrifuges utilize centrifugal force to separate components of a liquid from solid particles or a liquid-liquid mixture.

How Does a Centrifuge Work To Separate?

Medical centrifuges utilize centrifugal force to separate particulate matter from liquids. When centrifuged, the sample solution is spun at high speeds and the heavier particulate matter settles to the bottom of the centrifuge tube, while the lighter liquid components remain in the supernatant.

Centrifugation mainly serves to remove insoluble particles and improve detection accuracy.

The process of centrifuge separation

First take a quantitative amount of processed samples, evenly distribute the samples into centrifuge tubes, if you need to centrifuge more than one sample, make sure that the volume of the sample in each tube is the same, or add a counterweight tube to balance the centrifuge, place the centrifuge tubes symmetrically in the centrifuge's rotor to ensure that centrifugation equilibrium, set the centrifugation speed and time to start centrifugation. Remove the tubes at the end of centrifugation, taking care to avoid disturbing the sediment.

How To Balance a Centrifuge?

Odd number balance trick: 3+N

Arrange the equilateral triangles first, and center symmetry the remaining two by two.

Even number balancing trick: Two pairs of centers are symmetrical.

How To Use a Centrifuge?

The centrifugal speed and time required for the centrifugal operation are set individually through the operation panel.

Place the centrifuge tubes symmetrically to ensure that the weights of the test liquids in the tubes are balanced to optimize the centrifugation operation.

Press the lid of the centrifuge firmly.

After the bench top centrifuge has finished timing, the internal rotation speed will gradually return to zero.

Remove the centrifuge tubes from the rotor after the centrifugation operation and gently place them on the centrifuge tube rack.

What Is The Components Of A Centrifuge?

The structure of the lab centrifuges includes four main parts: drive system, various types of rotary head, temperature control and the whole machine control:

Centripetal Vs Centrifugal

What Is a Refrigerated Centrifuge?

Cryo-centrifuge is a kind of laboratory equipment for high-speed centrifugal separation in a low-temperature environment, which combines the two core functions of centrifugal force and precise temperature control, and is specially designed for processing temperature-sensitive samples (e.g., biological macromolecules, cells, blood components, etc.)

What Is High/Low Speed Centrifuge?

High-speed centrifuges are centrifuges with speeds between 10,000 and 30,000 rpm.

Low-speed centrifuges are centrifuges with speeds below 10,000 rpm.

What Is Hematocrit Centrifuge?

The Hematocrit Centrifuge is a specialized centrifuge for the rapid determination of hematocrit (HCT) in clinical laboratories. Its core function is to separate anticoagulated whole blood into red blood cell and plasma layers by centrifugation at high speed and to read the volume percentage of red blood cells in whole blood directly.

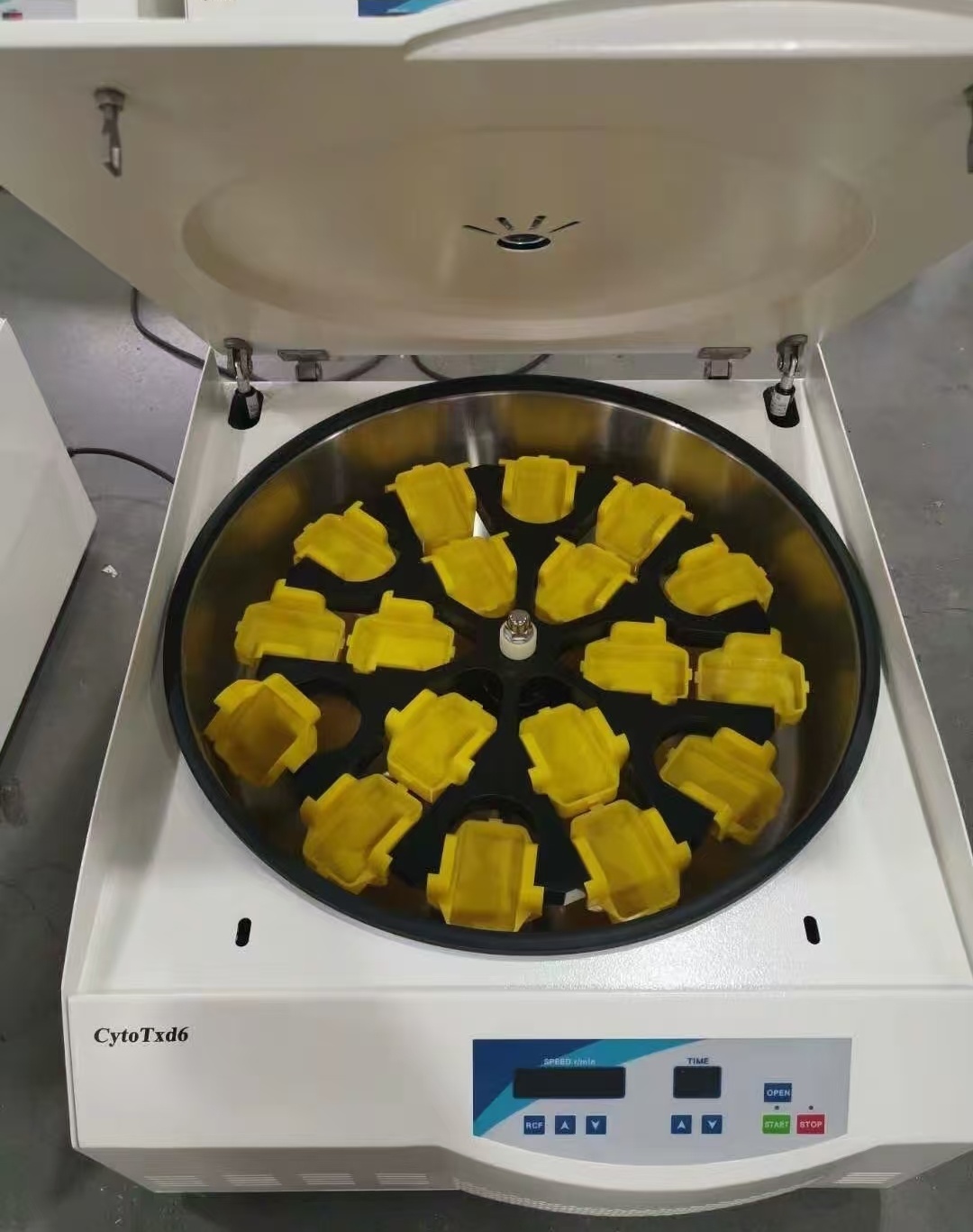

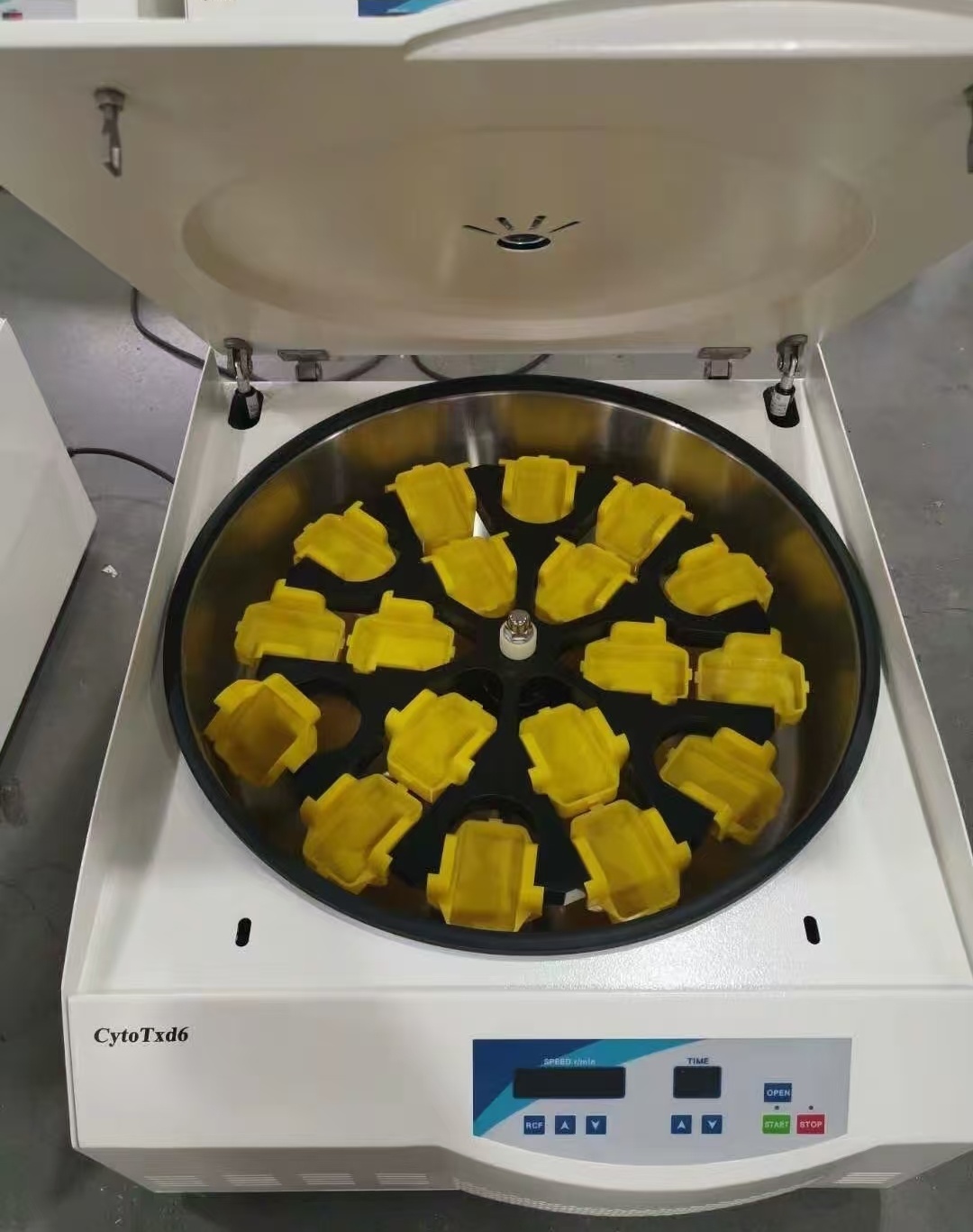

What Is Cyto Smear Liquid Centrifuge?

The Cyto Smear Liquid Centrifuge is a laboratory device designed for the preparation of high-quality cell smears by centrifugation at low speeds to settle cells from liquid samples (e.g., body fluids, fine-needle punctures, cultured cell suspensions) directly and uniformly onto slides while removing excess liquid.

Why Is a Centrifuge Important?

Table top centrifuges are widely and critically used as a separation and purification device in modern research and industry. With the continuous progress and innovation of science and technology, the technology of benchtop centrifuges is also constantly evolving to meet the needs of more efficient and precise experiments.

The application of variable frequency speed control technology is the electric centrifuge runs more smoothly, the speed control is precise, and the separation effect and repeatability are improved. Efficient cooling systems are especially important for experiments that deal with temperature-sensitive samples or require long periods of high-speed centrifugation.

In biomedical research the demand for centrifugal separation technology is getting higher and higher, the requirements for the separation and purification of nucleic acids, proteins and other biological macromolecules have increased dramatically, professional rotors and adapters can meet specific experimental requirements, such as cell culture, virus particle separation and so on. The innovation of centrifugal separation technology has broadened the application scope of centrifuges and provided more possibilities for scientific research.

What Are The Types Of Centrifuge?

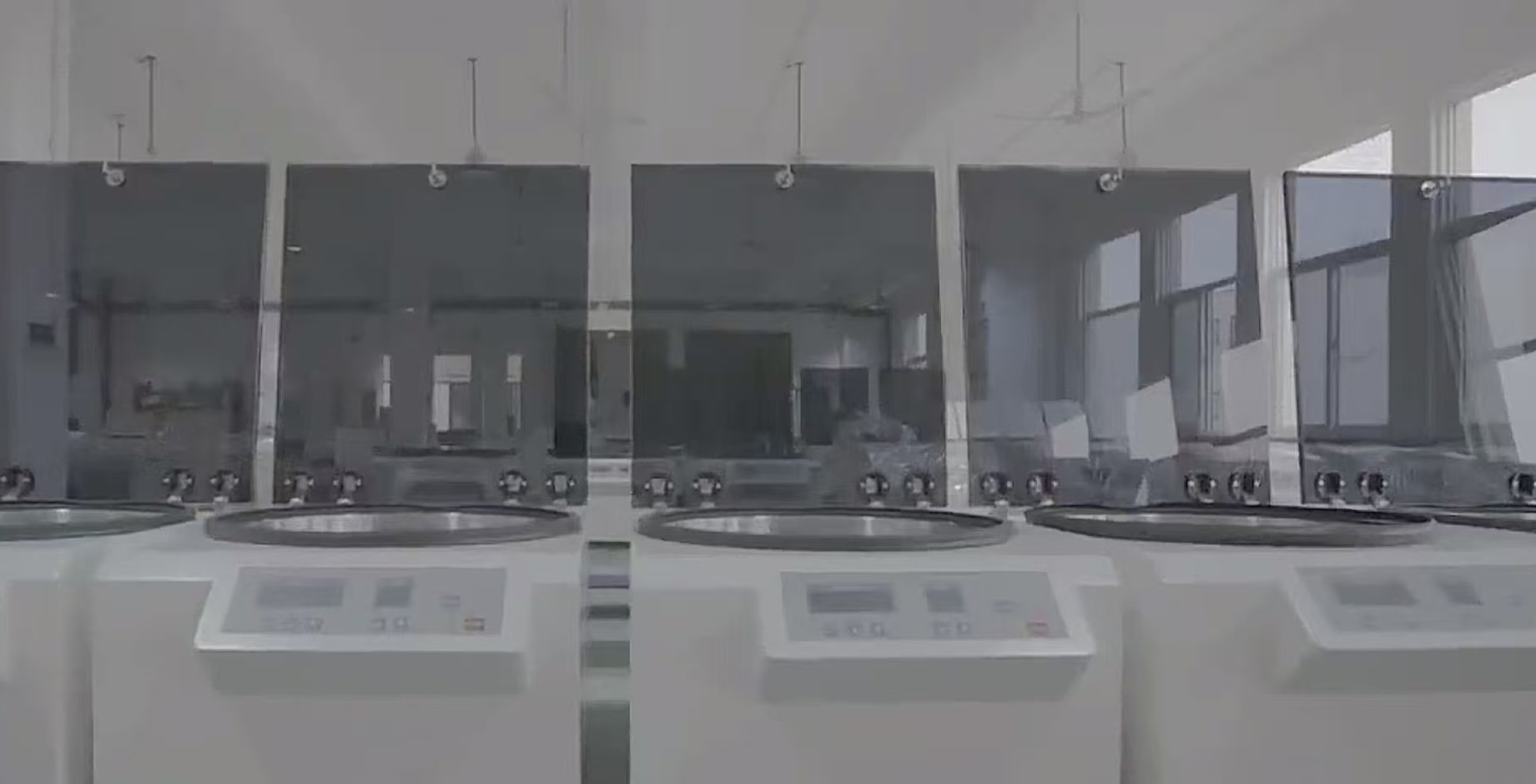

Bio centrifuges can be categorized into benchtop centrifuges and floor-standing centrifuges according to their structural form;

Scientific centrifuges can be categorized into large centrifuges and mini centrifuges according to capacity;

According to the rotational speed can be divided into low-speed centrifuges, high-speed centrifuges, ultra-speed centrifuges and ultra-high-speed centrifuges.

According to the temperature can be divided into room temperature centrifuge and refrigerated centrifuge.

According to the scope of application can also be divided into industrial laboratory centrifuge and medical laboratory centrifuge.

Industrial laboratory centrifuges are usually used for data acquisition and analysis, while medical laboratory centrifuges are mainly used in medical experiments, hospitals, pharmaceutical companies and biological research institutes.

What Is RCF in centrifuge?

Centrifuge test parameters are usually expressed in terms of relative centrifugal force (RCF) rather than rotational speed (RPM), because the actual centrifugal force varies with the radius of the centrifuge rotor at the same RPM.RCF is the ratio of centrifugal force to gravity (in × g).

RCF formula: RCF=1.118×10−5×r×(RPM)2

r: Centrifugal radius (cm, distance from the center of rotation to the bottom of the test tube).

How To Convert Centrifuge RPM To RCF g Force?

When looking at a automatic centrifuge, there are two ways to express speed: centrifugal force, g (acceleration due to gravity), and revolutions per minute, rpm. Where g is sometimes expressed as relative centrifugal force (RCF ), the relationship between the two is calculated as follows (r in cm).

RCF = g = 11.18x10-6xrx(rpm)2

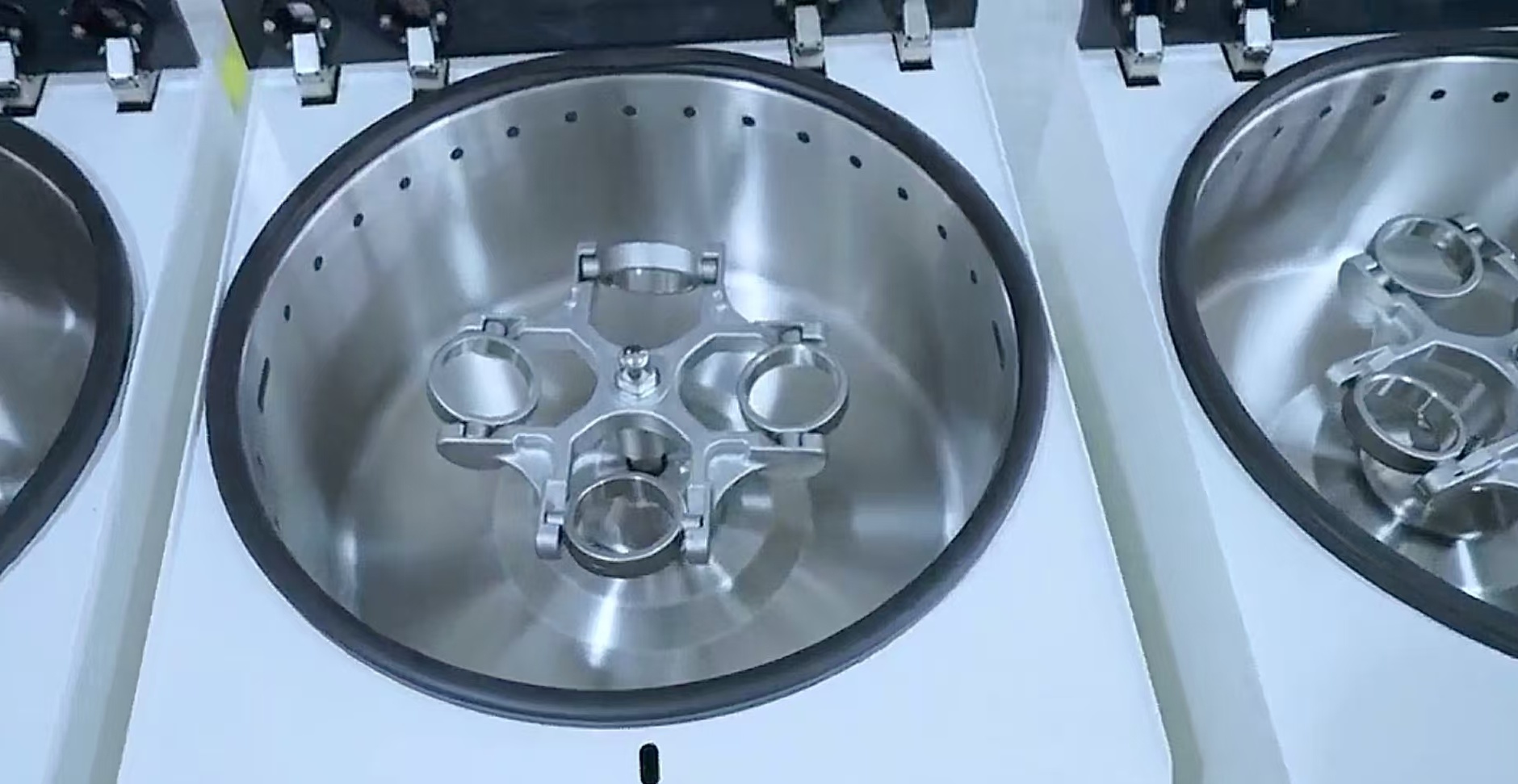

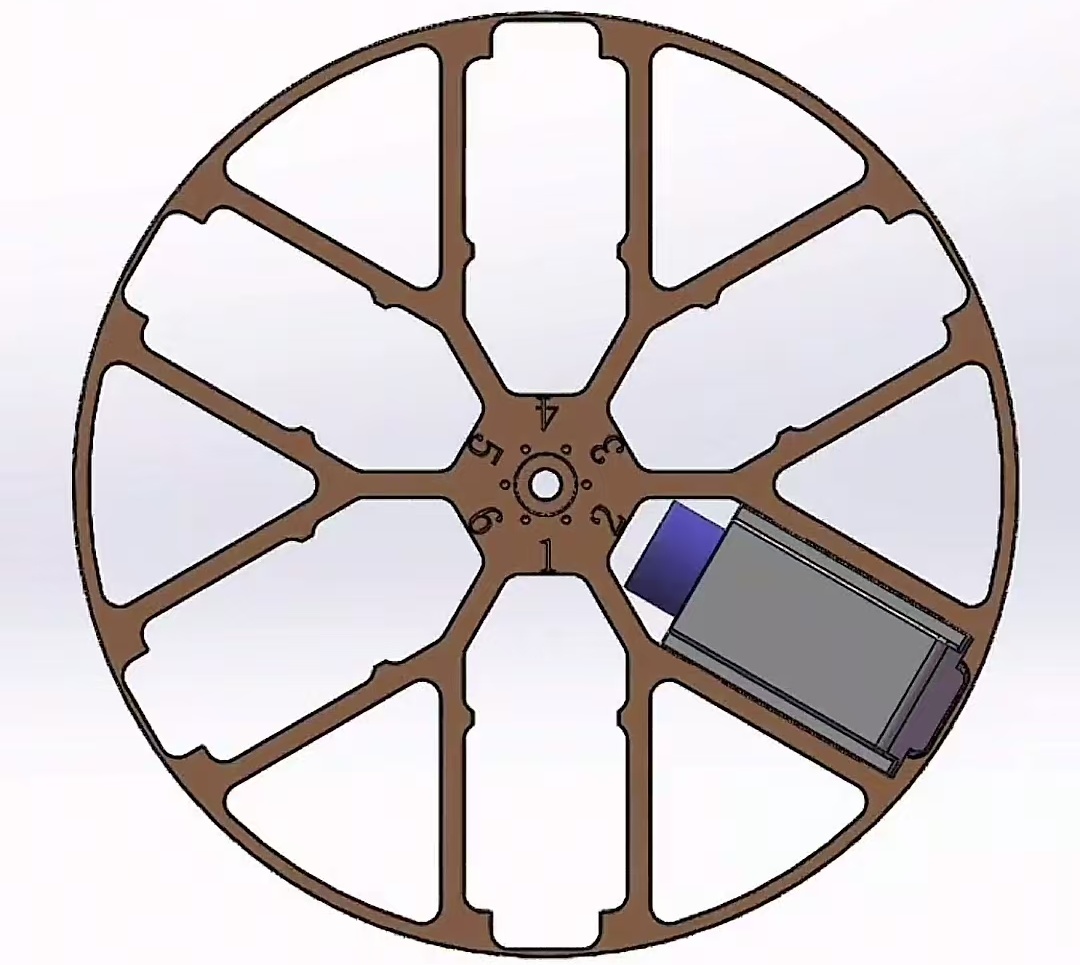

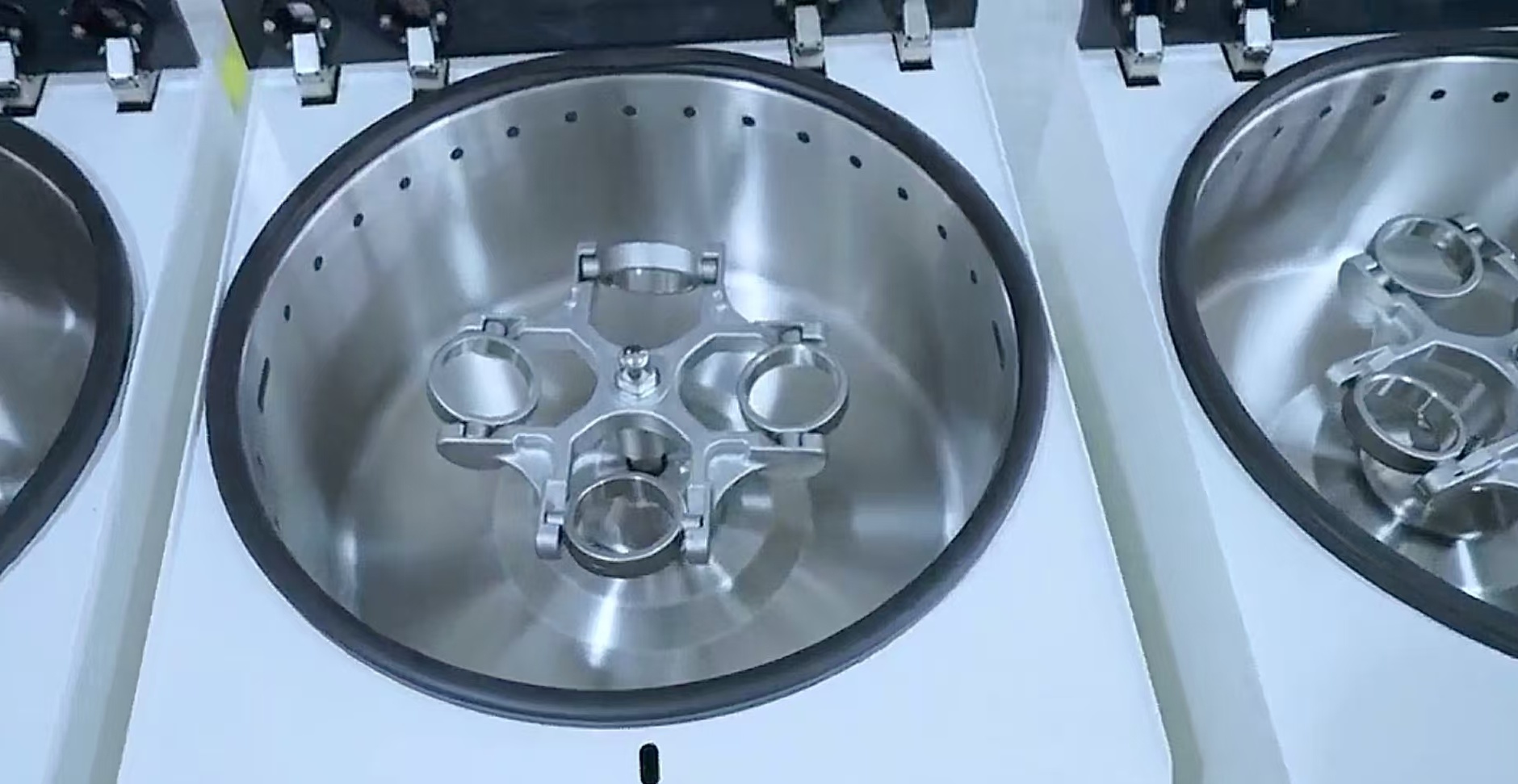

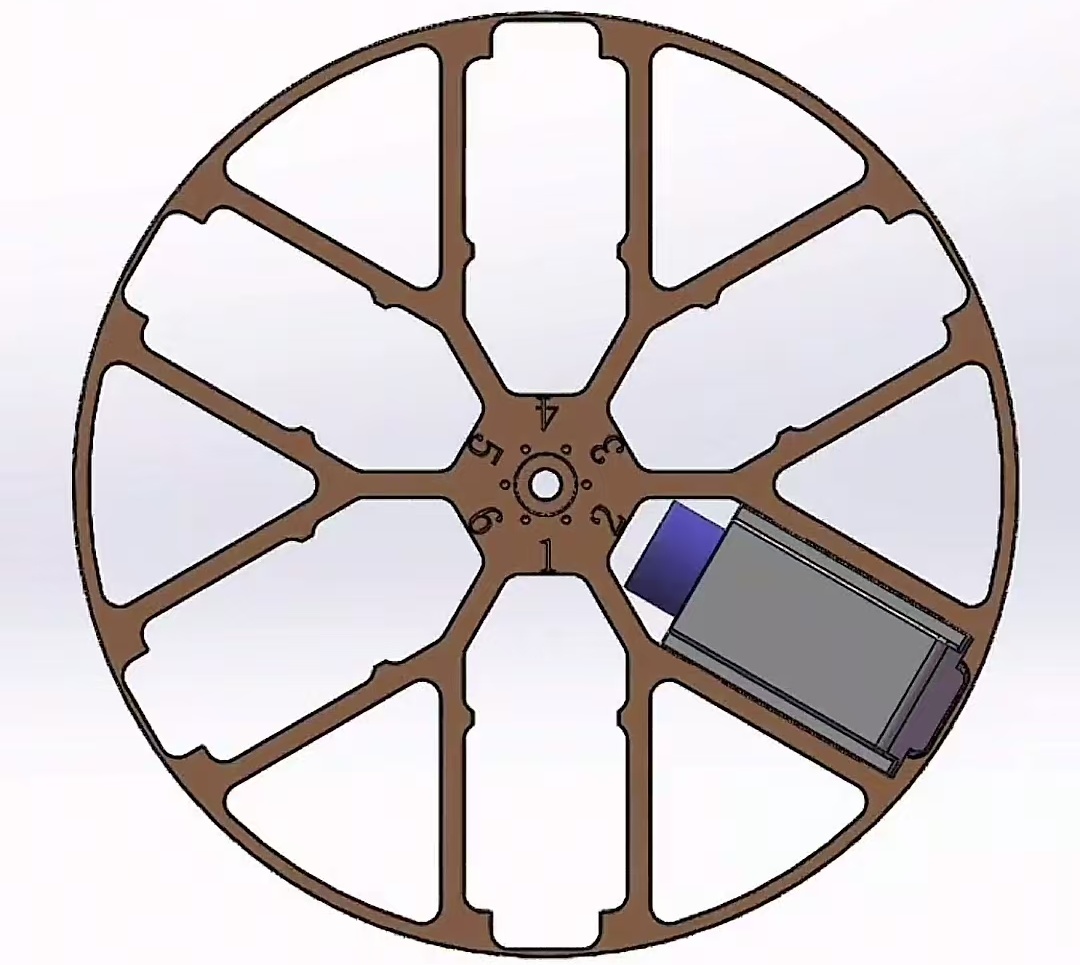

What Rotor Is Used In Centrifuge?

How To Choose The Right Rotor For Centrifuge?

If the centrifugal mixers have a small space with a high rotational speed, choose an angular rotor with a low center of gravity and low resistance. The angular rotor forms a 20-40 degree angle with the rotating shaft, and the sample will settle on the bottom and side walls.

If the centrifuge space is large and the rotational speed is low, choose the horizontal rotor which is favorable for stratified sampling, and the sample will settle at the bottom.

What Tube Is Need To In a Centrifuge?

How Full Should The Centrifuge Tube Be?

Do not exceed the maximum capacity labeled for the centrifuge tube you are using on the tube itself.

Do not exceed the maximum working capacity specified for that type of centrifuge tube in the instructions for the rotor (or adapter) you are using.

The centrifuge owner's manual and the instructions for the rotor/adapter itself will clearly list the types of centrifuge tubes allowed for each adapter and their corresponding maximum working capacity.

How To Sterilize Centrifuge Tubes?

Autoclavable:

Applicable materials: polypropylene (PP), polycarbonate (PC) and other plastic centrifuge tubes.

Conditions: 121°C, 20 minutes. It is necessary to use it immediately after sterilization to avoid that the membrane can not be dried after wetting.

High temperature sterilizer:

Applicable materials: centrifuge tubes of various materials.

Conditions: Heat to above 100°C for 15-30 minutes.

Chemical sterilizers:

For centrifuge tubes made of various materials. For non-heat-resistant materials.

Method: Soak or wipe the surface of the centrifuge tube with 70% alcohol or bleach, paying attention to the soaking time and concentration.

Caution:

Ensure that the centrifuge tube caps are well sealed to prevent liquid leakage.

Sterilized centrifuge tubes should be cooled in a sterile environment.

If chemical sterilizers are used, pay attention to the residue problem and neutralize if necessary.

For more detailed information, it is recommended to consult the relevant laboratory manuals or guidelines.

How Does a Centrifuge Separate Blood?

What Happens If You Centrifuge Blood Too Soon?

Centrifugation of blood at speeds (centrifugal force) exceeding the recommended range can lead to sample destruction and distortion of test results, e.g. impairment of blood cell function, hemolysis (rupture of red blood cells), release of hemoglobin into the plasma/serum, and damage to the equipment.

How Fast Does a Blood Centrifuge Spin?

Separation of different blood products by centrifuge

1. CGF - Stratified centrifugation (2400 rpm × 2 min + 2700 rpm × 4 min + 3000 rpm × 4 min).

2. PRP - 3000 rpm, centrifugation for 10 min.

3. APRF - 2450 rpm, 4 min.

4. IPRF - 2850 rpm, 4 min.

How To Separate Plasma From Blood With a Centrifuge?

Centrifuge separation of plasma at a speed setting of 1,500 - 3,000 × g for 10-15 minutes using a horizontal rotor. Yellowish clear plasma was obtained.

How To Separate Serum From Blood With a Centrifuge?

Separate the serum in a centrifuge set at 1,500 - 3,000 × g for 10-15 minutes using a horizontal rotor. Pale yellow serum without fibrinogen was obtained.

How Long Should Blood Sit Before Centrifuging?

Does Centrifuge Damage Cells?

Centrifugation above the recommended range results in cell destruction, and cells lysed when the centrifugation force is greater than the cell tolerance threshold.

Does Centrifuge Damage Sperm?

Centrifugal forces above the recommended range result in destruction of sperm, breakage of the sperm tail and loss of sperm motility.

What Does Centrifuge Do To DNA?

Extraction of DNA: Gram-positive bacteria as an example

1. Add 100ul TE buffer and 100ul lysozyme solution into 1.5ml centrifuge tube, scrape down the bacteria on the plate with inoculation ring and transfer them to the centrifuge tube, vortex for about 15s and mix them well, and then take a water bath at 37℃ for 30-60min.

2. Add 250ul of Buffer PL preheated at 65℃, vortex for 30s and mix well, water bath at 65℃ for 10min. during the water bath, shake the centrifuge tube vigorously for several times every 2~3 minutes to help the release of DNA.

3. Add 350ul of Buffer K, cap the tube, shake vigorously for 15s, and vortex for 30s. centrifuge at 13000 rpm for 5min.

4. Place the column in a 2 ml centrifuge tube, pour the centrifugation supernatant from step 3 into the column, cap the tube, and centrifuge at 12,000 rpm for 30-60 s.

5. Discard the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, add 500 ul of Buffer WA to the column, cap the tube, and centrifuge at 12,000 rpm for 30-60 s. *Confirm that the ONA is released in the column. -Make sure that anhydrous ethanol has been added to the Buffer WA.

6. Discard the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, add 600 ul of Buffer WB to the column, cap the tube, and centrifuge at 12000 rpm for 30-60 s. *Confirm that anhydrous ethanol has been added to Buffer WA.

Confirm that anhydrous ethanol has been added to the Buffer WB.

7. Dispose of the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, cap the tube and centrifuge at 12000 rpm for 2 min.

*If the centrifuge cannot reach 14000 rpm, centrifuge at the highest speed for 2 min.

*Do not omit this step, otherwise the purified nucleic acid may be mixed with ethanol, which may affect the subsequent experimental results.

8. Discard the 2ml centrifuge tube, put the nucleic acid purification column into a clean 1.5ml centrifuge tube, blow the fan for 5min, add 100~200p165℃ preheated Buffer TE into the purification column, cover the tube, let it stand at room temperature for 2min, and then centrifuge at 12000 rpm for 30s.

9. Discard the purification column, the eluted DNA can be used immediately for various molecular biology experiments; or store the DNA at -20'℃ for backup.

How Much Does a Centrifuge Cost?

It wouldn’t be right to mention one fixed amount.

The centrifuge price will vary from model to model.

To know the exact price, you can ask your preferred manufacturer to provide a quotation for the type of centrifuge you want.

How Many Rpm/Fast Does a Centrifuge Spin?

Centrifugal separation equipment typically operate at speeds between 100 - 100,000 rpm:

Low-speed centrifuges: speeds usually less than 10,000 rpm, suitable for separating larger cells, bacteria or precipitating insoluble matter.

High speed centrifuges: speeds between 10,000 - 30,000 rpm, suitable for separating biological macromolecules such as organelles and viruses.

Ultra-high speed centrifuges: speeds greater than 30,000 rpm, used for ultra-fast centrifugation, such as protein purification and nucleic acid extraction.

How To Clean a Centrifuge?

In the inner chamber of the centrifuge, several cleaning heads or cleaning tubes are set up, and the centrifuge can be cleaned inside the centrifuge without opening the cover or during operation.

Focus on the following parts:

1) Cleaning of the bottom surface of the drum and the bearing seat parts;

2) Surface of the liquid stopper plate and the outer surface of the drum cylinder;

3) Inner surface of the drum cylinder;

4) Inner surface of the flip cover and the surface of the feeding, scraper and other devices;

5) Inner surface of the shell.

Common problems and solutions of centrifuges.

Centrifuge tube sample leveling problems, if the sample is not balanced, it will lead to electrode shaft bending over time, affecting the life of the centrifuge.

After an emergency power failure during operation, the door cover can be opened from the emergency hole on the side of the device to remove the sample.

If the equipment cannot be started after a power failure, the circuit board may be faulty, or the fuse at the power supply may be burnt.

If the machine fails to start normally, the door cover may not be tight, and the display will indicate a system failure.

How To Maintain a Centrifuge?

I. Daily cleaning and inspection

1. After each use of the centrifuge, the dirt and residue inside and outside the centrifugal chamber should be cleaned in time to avoid corrosion of the equipment or affect the centrifugal effect.

2. Regularly check whether the centrifuge power cord, plug and socket is intact, no damage, aging phenomenon, to ensure electrical safety.

3. Observe whether there is abnormal sound, vibration or odor during the operation of the centrifuge, if any, should be stopped in time for inspection.

Second, regularly check the lubrication system

1. Regularly check the centrifuge bearings, transmission gears and other lubrication parts to ensure that the lubricating grease is sufficient and clean.

2. According to the requirements of the equipment manual, regular replacement or supplementation of lubricating grease to ensure smooth and stable operation of the equipment.

Third, the motor and belt maintenance

1. Regularly check the running condition of the motor, including temperature, noise, etc., if there is any abnormality, it should be dealt with in time.

2. The motor belt should be kept at a proper tension to avoid loose or too tight resulting in reduced transmission efficiency or belt wear.

Fourth, bearing and seal maintenance

1. Regularly check the wear and tear of the bearings, if there is serious wear and tear or abnormalities should be replaced in a timely manner.

2. The seals should be checked regularly for their integrity, and should be replaced in time if they are aging or broken, in order to prove the sealing performance of the centrifuge.

V. Cleaning and maintenance after shutdown

1. After the centrifuge shutdown, its internal and external comprehensive cleaning to avoid residues on the equipment caused by corrosion.

2. Cleaning should be wiped with a soft cloth, avoid the use of corrosive cleaning agents or tools.

Sixth, maintenance and maintenance records

1. The establishment of centrifuge maintenance and maintenance record sheet, a detailed record of each maintenance and maintenance of time, content, replacement of parts and other information.

2. Through the record can be timely understanding of the maintenance status of the equipment, for the future maintenance and repair to provide a basis.

Seven, professional maintenance and overhaul

1. If encountering centrifuge failure or abnormal situation, should contact the professional maintenance personnel in time to deal with, do not privately disassemble or repair.

2. Regularly carry out comprehensive overhaul of the centrifuge in order to find and solve potential problems and ensure the long-term stable operation of the equipment.

What Are The Rules For Using a Centrifuge?

Before starting the centrifuge each time, the screws between the rotor and the motor shaft must be tightened.

Before centrifugation, the tube caps must be tightened.

The centrifuge tubes to be placed in the rotor must be of the same type and the weight of the tubes must be balanced.

Symmetrical placement of centrifuge tubes.

Do not open the lid until the centrifuge has come to a complete stop to prevent injury.

Why Is It Important Not To Stop The Centrifuge Abruptly?

Suddenly stopping the speed centrifuge (Abruptly stop) can have catastrophic consequences, such as equipment damage motor scrapping, destruction of samples in the centrifuge, risks to personal safety and contaminant spread.

How To Open Centrifuge Lid?

Before opening the cover, wait for the rotor to come to a complete stop (tachometer zeroed) and the refrigeration model needs to be temperature balanced (to prevent condensation and icing), otherwise there will be serious consequences.

How To Buy A Centrifuge Machine China?

Importing high performance benchtop centrifuge machine from China can be difficult for those who are new to international imports.

Purchasing from a reputable manufacturer and supplier eliminates hassle of logistics, as they handle the safe and reliable delivery of the product directly to your place.

When buying the pharma centrifuges, it is important to keep the following points in mind:

1. Confirm that your selected supplier can securely export and deliver the machine, and ensure that your agreement includes all essential shipping information.

2. Choose the delivery way (by sea, air, or express) based on your preference.

3. Remember to factor in duty imports and taxes when calculating the total cost.

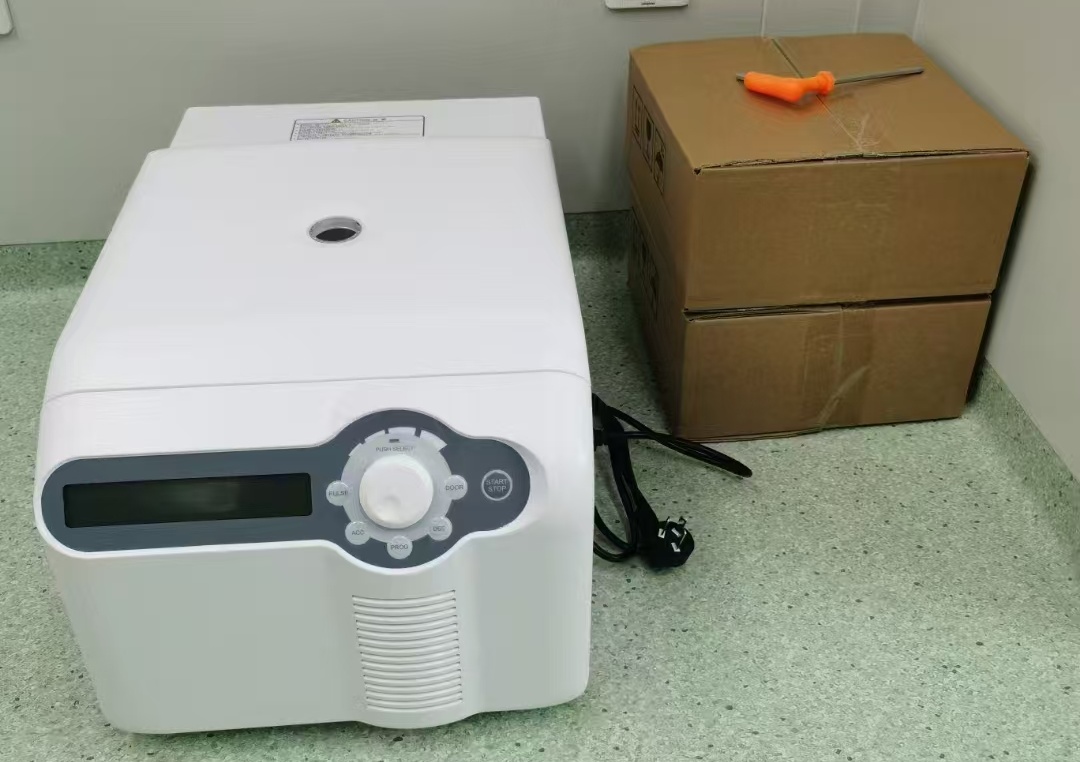

How Does a Manufacturer Deliver The Centrifuge Machine?

Safe shipping is so important as quality manufacturing.

A responsible manufacturer should deliver your centrifuge laboratory safely.

Most centrifuge manufacturers use export cartoon case to pack the device.

You should read all the necessary instructions available on the sides of the boxes before boxing.

Is There Any Warranty On Centrifuge Machine?

For optimal performance, it is important to regularly maintain your micro centrifuge, so it can operate efficiently for an extended period. It is essential to be aware of the warranty coverage for your equipment, as it ensures that any manufacturing issues will be repaired at no additional cost by the supplier. Therefore, it is recommended to purchase a prp centrifuge from a manufacturer that offers warranty services —Cialan.

Reputable prp centrifuge machine manufacturers typically provide a 1-year warranty. for example, offers complimentary repair and maintenance services during the first year.

Before purchasing a platelet rich plasma centrifuge, it is advisable to review the warranty period and other associated terms and conditions.

What After-Sale Service Does A Centrifuge Machine?

The reliable china centrifuge machine suppliers offers the following after-sale services:

1. Secure product delivery.

2. Thorough inspection prior to installation.

3. Complimentary online guidance for device installation and maintenance.

4. Free training for your users.

5. Regular assessments of your cell centrifuge.

Can You Do OEM&ODM For Centrifuge Machine?

Yes, Cialan can do OEM#OEM for our users, just send us your requirements for bench centrifuge.

Where To Find Centrifuge Machine Manufacturers?

Numerous online directories can connect you with pharmacy grade refrigerator manufacturers.

A simple search for "top-rated centrifuge for laboratory manufacturers" yields multiple options. However, it's essential to exercise caution when selecting a manufacturer from online search results. Before making a decision, conduct thorough research on the company's background and reputation. Look up reviews on “Google” and reputable review sites to gauge their credibility.

Additionally, It's also crucial to review their portfolio of request that potential manufacturers share examples of their previous work to ensure they meet your standards.

How To Choose A Right Centrifuge Machine?

Horizontal centrifuges need to be purchased with attention to factors such as speed, temperature, capacity, rotor, control system and motor. The rotational speed should be determined according to the quality of the sample and the type of rotor, the temperature should be selected according to the nature of the sample, and the capacity should match the workload.

Rotor selection should be based on separation purpose and sample characteristics, control system should be user-friendly and safety and security features, and motor should be selected as carbon brushless motor to reduce pollution and noise. In addition, noise and accessories should also be considered.

What Should You Look For In The Best Centrifuge Machine?

The best centrifuge has efficient control of speed and temperature to ensure rotor safety, low vibration and noise, long service life and low maintenance cost.

Our comprehensive Centrifuge Machine FAQ Guide simplifies the process by detailing how centrifugation machine work, common problems, and best maintenance practices. It also addresses common questions such as “Centrifuge Rotor Types” and “Centrifuge Tube Types,” equipping you with the knowledge you need to make informed decisions.

Find out why centrifuge machines are the first choice for separating, purifying and concentrating samples from sample solutions. With their efficient design, low noise levels and wide range of applications, centrifuge machines in laboratory are guaranteed to meet the requirements of high-quality and precise experiments while ensuring their safety and reliability.

This guide also provides a reference for the time and speed required to separate blood and clarifies how blood centrifuge machines can be compliant and risk-free separation equipment. Whether you're launching a new experimental department or upgrading existing instrumentation, this guide has you covered.

Don't miss this important resource designed to maximize the matching of efficient laboratory centrifuges to your samples. Read the complete FAQ guide now!

What Is Centrifuge?

Lab centrifuge is an instrument that utilizes centrifugal force to separate components of different densities or particle sizes in a mixture, and it is an indispensable basic equipment in the fields of biochemistry, molecular biology, clinical medicine, pharmacy, chemical industry and so on.

What Is Centrifugal Force?

In Newtonian mechanics, centrifugal force is an inertial force (also known as “virtual force” or “pseudo-force”) that appears to act on all objects when viewed in a rotating frame of reference, and is directed away from the axis of rotation that is parallel to the axis of rotation and passes through the origin of the coordinate system.

What Is Centrifugation?

The principle of centrifuge technology is to utilize the strong centrifugal force generated when an object is rotating at high speed to cause suspended particles placed in a rotating body to settle or float, thus enabling some particles to achieve concentration or separation from other particles.

What Is The Working Principle Of Centrifuge?

Centrifuge uses are in simulating the effect of the earth's gravity field through centrifugal force, prompting objects to undergo a settling motion, thus realizing the separation of components of different densities and molecular levels in substances. The application of centrifugation separation technique is known as separation technology, which is now widely used in scientific research and production sectors, and has become one of the important instruments and equipment for modern scientific research.

What Is The Application Of a Centrifuge?

University laboratories: Centrifugal machines are often utilized for the separation and extraction of biological material samples such as cells, proteins, viruses, and DNA/RNA. It is capable of rapid cooling, precise and efficient stratification, safe and smooth.

Hospital laboratory, blood transfusion department, pathology laboratory: Blood centrifuge is commonly used for separation of blood, body fluids, pathology samples. It has the advantages of large flux, multi-rotor selection, and multi-purpose.

Bio-pharmaceutical enterprises: Centrifuges are commonly used in the collection of bacterial fermentation fluid, protein precipitation and purification, and other large-capacity biological samples extraction and preparation work. It has the advantages of large capacity, fast centrifugal speed, good effect, low noise, corrosion-resistant rotor and so on.

Blood station laboratory: Centrifuga are mainly used for separating blood samples and testing their safety indexes. And in the component department, it is mainly used for the separation and preparation of component blood. It has the advantages of large capacity, direct processing of blood bags, and customized display function in blood station.

CDC Laboratory Section: Clinical centrifuges are mainly used for the separation and extraction of various samples such as cells, bacteria, viruses, molds, body fluids and blood. It has the advantages of safe operation and stable operation.

What Does a Centrifuge Do?

Centrifuges lab are widely used in hospitals and laboratories for the separation of liquid mixtures of organisms, chlorophyll, protein nucleic acids and other liquids. Centrifuges utilize centrifugal force to separate components of a liquid from solid particles or a liquid-liquid mixture.

How Does a Centrifuge Work To Separate?

Medical centrifuges utilize centrifugal force to separate particulate matter from liquids. When centrifuged, the sample solution is spun at high speeds and the heavier particulate matter settles to the bottom of the centrifuge tube, while the lighter liquid components remain in the supernatant.

Centrifugation mainly serves to remove insoluble particles and improve detection accuracy.

The process of centrifuge separation

First take a quantitative amount of processed samples, evenly distribute the samples into centrifuge tubes, if you need to centrifuge more than one sample, make sure that the volume of the sample in each tube is the same, or add a counterweight tube to balance the centrifuge, place the centrifuge tubes symmetrically in the centrifuge's rotor to ensure that centrifugation equilibrium, set the centrifugation speed and time to start centrifugation. Remove the tubes at the end of centrifugation, taking care to avoid disturbing the sediment.

How To Balance a Centrifuge?

Odd number balance trick: 3+N

Arrange the equilateral triangles first, and center symmetry the remaining two by two.

Even number balancing trick: Two pairs of centers are symmetrical.

How To Use a Centrifuge?

The centrifugal speed and time required for the centrifugal operation are set individually through the operation panel.

Place the centrifuge tubes symmetrically to ensure that the weights of the test liquids in the tubes are balanced to optimize the centrifugation operation.

Press the lid of the centrifuge firmly.

After the bench top centrifuge has finished timing, the internal rotation speed will gradually return to zero.

Remove the centrifuge tubes from the rotor after the centrifugation operation and gently place them on the centrifuge tube rack.

What Is The Components Of A Centrifuge?

The structure of the lab centrifuges includes four main parts: drive system, various types of rotary head, temperature control and the whole machine control:

| Drive system | Adopting brushless inverter motor has several advantages, such as maximum torque output at different speeds, simple maintenance, no need to replace carbon brushes regularly, reducing maintenance costs. |

| Temp. control system | Laboratory centrifuges are mainly divided into two control methods, low temperature and room temperature. The low temperature control model provides a first-class compressor without fluorine refrigeration, which realizes precise temperature control and is more convenient for laboratory operation. |

| Control and display system | Adopting microprocessor control, equipped with digital or LCD screen display control panel, supporting a variety of intelligent adjustment and display functions. It can set rpm and rcf and display the actual value in real time, which reduces the trouble of calculation. With program memory and storage function, it is convenient for management and use in laboratory environment. |

| Safety Protection System | Including automatic lid locking, over-temperature, over-speed, out-of-balance and many other protection mechanisms to guarantee the operation safety of the centrifuge. |

Centripetal Vs Centrifugal

| Centripetal | Centrifugal |

| In classical mechanics, the centripetal force is the combined external force acting toward the center of the circle when an object moves along a circular or curved orbit. Centripetal force is not really a force, but a manifestation of the combined external force. The term “centripetal force” is named after the effect produced by this combined external force. This effect can be produced by any of the forces of elasticity, gravity, or friction. It can also be provided by the combined force of several forces or by the partial force of several forces. | Centrifugal force, an imaginary inertial force, does not exist in reality. When an object moves in circular motion, the centripetal acceleration produces a force-like effect in the object's coordinate system, similar to having a force acting in the centrifugal direction, hence the name centrifugal force. When an object is in non-linear circular motion, the object is located in a Newtonian environment of motion and the force felt by the object is not real. |

What Is a Refrigerated Centrifuge?

Cryo-centrifuge is a kind of laboratory equipment for high-speed centrifugal separation in a low-temperature environment, which combines the two core functions of centrifugal force and precise temperature control, and is specially designed for processing temperature-sensitive samples (e.g., biological macromolecules, cells, blood components, etc.)

What Is High/Low Speed Centrifuge?

High-speed centrifuges are centrifuges with speeds between 10,000 and 30,000 rpm.

Low-speed centrifuges are centrifuges with speeds below 10,000 rpm.

What Is Hematocrit Centrifuge?

The Hematocrit Centrifuge is a specialized centrifuge for the rapid determination of hematocrit (HCT) in clinical laboratories. Its core function is to separate anticoagulated whole blood into red blood cell and plasma layers by centrifugation at high speed and to read the volume percentage of red blood cells in whole blood directly.

What Is Cyto Smear Liquid Centrifuge?

The Cyto Smear Liquid Centrifuge is a laboratory device designed for the preparation of high-quality cell smears by centrifugation at low speeds to settle cells from liquid samples (e.g., body fluids, fine-needle punctures, cultured cell suspensions) directly and uniformly onto slides while removing excess liquid.

Why Is a Centrifuge Important?

Table top centrifuges are widely and critically used as a separation and purification device in modern research and industry. With the continuous progress and innovation of science and technology, the technology of benchtop centrifuges is also constantly evolving to meet the needs of more efficient and precise experiments.

The application of variable frequency speed control technology is the electric centrifuge runs more smoothly, the speed control is precise, and the separation effect and repeatability are improved. Efficient cooling systems are especially important for experiments that deal with temperature-sensitive samples or require long periods of high-speed centrifugation.

In biomedical research the demand for centrifugal separation technology is getting higher and higher, the requirements for the separation and purification of nucleic acids, proteins and other biological macromolecules have increased dramatically, professional rotors and adapters can meet specific experimental requirements, such as cell culture, virus particle separation and so on. The innovation of centrifugal separation technology has broadened the application scope of centrifuges and provided more possibilities for scientific research.

What Are The Types Of Centrifuge?

Bio centrifuges can be categorized into benchtop centrifuges and floor-standing centrifuges according to their structural form;

Scientific centrifuges can be categorized into large centrifuges and mini centrifuges according to capacity;

According to the rotational speed can be divided into low-speed centrifuges, high-speed centrifuges, ultra-speed centrifuges and ultra-high-speed centrifuges.

According to the temperature can be divided into room temperature centrifuge and refrigerated centrifuge.

According to the scope of application can also be divided into industrial laboratory centrifuge and medical laboratory centrifuge.

Industrial laboratory centrifuges are usually used for data acquisition and analysis, while medical laboratory centrifuges are mainly used in medical experiments, hospitals, pharmaceutical companies and biological research institutes.

What Is RCF in centrifuge?

Centrifuge test parameters are usually expressed in terms of relative centrifugal force (RCF) rather than rotational speed (RPM), because the actual centrifugal force varies with the radius of the centrifuge rotor at the same RPM.RCF is the ratio of centrifugal force to gravity (in × g).

RCF formula: RCF=1.118×10−5×r×(RPM)2

r: Centrifugal radius (cm, distance from the center of rotation to the bottom of the test tube).

How To Convert Centrifuge RPM To RCF g Force?

When looking at a automatic centrifuge, there are two ways to express speed: centrifugal force, g (acceleration due to gravity), and revolutions per minute, rpm. Where g is sometimes expressed as relative centrifugal force (RCF ), the relationship between the two is calculated as follows (r in cm).

RCF = g = 11.18x10-6xrx(rpm)2

What Rotor Is Used In Centrifuge?

| Vertical Rotor | The centrifuge tube is placed completely vertically and the particles settle outward horizontally in the radial direction during rotation. |

| Fixed Angle Rotor | The sample aperture is embedded in the rotor body at a fixed angle (usually 30° to 45°) and the aperture wall is parallel to the axis of rotation. The tube remains tilted during rotation and the particles settle obliquely along the tube wall. |

| Swing rotor | A rotor with a freely swinging basket in which the centrifuge tube is placed vertically. The basket is vertical at rest; when rotating, the basket is thrown to the horizontal position and the centrifuge tube is perpendicular to the rotation axis. |

How To Choose The Right Rotor For Centrifuge?

If the centrifugal mixers have a small space with a high rotational speed, choose an angular rotor with a low center of gravity and low resistance. The angular rotor forms a 20-40 degree angle with the rotating shaft, and the sample will settle on the bottom and side walls.

If the centrifuge space is large and the rotational speed is low, choose the horizontal rotor which is favorable for stratified sampling, and the sample will settle at the bottom.

What Tube Is Need To In a Centrifuge?

How Full Should The Centrifuge Tube Be?

Do not exceed the maximum capacity labeled for the centrifuge tube you are using on the tube itself.

Do not exceed the maximum working capacity specified for that type of centrifuge tube in the instructions for the rotor (or adapter) you are using.

The centrifuge owner's manual and the instructions for the rotor/adapter itself will clearly list the types of centrifuge tubes allowed for each adapter and their corresponding maximum working capacity.

How To Sterilize Centrifuge Tubes?

Autoclavable:

Applicable materials: polypropylene (PP), polycarbonate (PC) and other plastic centrifuge tubes.

Conditions: 121°C, 20 minutes. It is necessary to use it immediately after sterilization to avoid that the membrane can not be dried after wetting.

High temperature sterilizer:

Applicable materials: centrifuge tubes of various materials.

Conditions: Heat to above 100°C for 15-30 minutes.

Chemical sterilizers:

For centrifuge tubes made of various materials. For non-heat-resistant materials.

Method: Soak or wipe the surface of the centrifuge tube with 70% alcohol or bleach, paying attention to the soaking time and concentration.

Caution:

Ensure that the centrifuge tube caps are well sealed to prevent liquid leakage.

Sterilized centrifuge tubes should be cooled in a sterile environment.

If chemical sterilizers are used, pay attention to the residue problem and neutralize if necessary.

For more detailed information, it is recommended to consult the relevant laboratory manuals or guidelines.

How Does a Centrifuge Separate Blood?

| Samples | RCF | Time | Temp. |

| Plasma/serum | 1,500 - 3,000 × g | 10-15 min | RT |

| Platelets | 200 - 400 × g | 15 min | 22°C |

| Red blood cells | >3,000 × g | 10 min | 4°C |

What Happens If You Centrifuge Blood Too Soon?

Centrifugation of blood at speeds (centrifugal force) exceeding the recommended range can lead to sample destruction and distortion of test results, e.g. impairment of blood cell function, hemolysis (rupture of red blood cells), release of hemoglobin into the plasma/serum, and damage to the equipment.

How Fast Does a Blood Centrifuge Spin?

Separation of different blood products by centrifuge

1. CGF - Stratified centrifugation (2400 rpm × 2 min + 2700 rpm × 4 min + 3000 rpm × 4 min).

2. PRP - 3000 rpm, centrifugation for 10 min.

3. APRF - 2450 rpm, 4 min.

4. IPRF - 2850 rpm, 4 min.

How To Separate Plasma From Blood With a Centrifuge?

Centrifuge separation of plasma at a speed setting of 1,500 - 3,000 × g for 10-15 minutes using a horizontal rotor. Yellowish clear plasma was obtained.

How To Separate Serum From Blood With a Centrifuge?

Separate the serum in a centrifuge set at 1,500 - 3,000 × g for 10-15 minutes using a horizontal rotor. Pale yellow serum without fibrinogen was obtained.

How Long Should Blood Sit Before Centrifuging?

Separation of plasma |

EDTA | No need to rest, mix 8-10 times with gentle inversion immediately after blood collection, centrifuge directly Prevent coagulation and cell metabolism from affecting results |

| Sodium citrate | Allow to stand for 15-30 minutes (after mixing) until bubbles disappear and blood is homogenized Ensure anticoagulants are well mixed to avoid localized coagulation | |

| Heparin | Leave for 5-10 minutes (after mixing) to equilibrate temperature Reduces errors due to temperature fluctuations during centrifugation. | |

Separation of serum |

Blood coagulation | 30-60 minutes (room temperature) The blood collection tube is tilted at 30° to promote clot contraction (shorten to 30 minutes to see if the clot is firm). |

| Complete contraction | Extend to 2 hours (if necessary) Samples with coagulation disorders (e.g., liver disease) should be allowed to stand for longer periods until clear serum is obtained. |

Does Centrifuge Damage Cells?

Centrifugation above the recommended range results in cell destruction, and cells lysed when the centrifugation force is greater than the cell tolerance threshold.

Does Centrifuge Damage Sperm?

Centrifugal forces above the recommended range result in destruction of sperm, breakage of the sperm tail and loss of sperm motility.

What Does Centrifuge Do To DNA?

Extraction of DNA: Gram-positive bacteria as an example

1. Add 100ul TE buffer and 100ul lysozyme solution into 1.5ml centrifuge tube, scrape down the bacteria on the plate with inoculation ring and transfer them to the centrifuge tube, vortex for about 15s and mix them well, and then take a water bath at 37℃ for 30-60min.

2. Add 250ul of Buffer PL preheated at 65℃, vortex for 30s and mix well, water bath at 65℃ for 10min. during the water bath, shake the centrifuge tube vigorously for several times every 2~3 minutes to help the release of DNA.

3. Add 350ul of Buffer K, cap the tube, shake vigorously for 15s, and vortex for 30s. centrifuge at 13000 rpm for 5min.

4. Place the column in a 2 ml centrifuge tube, pour the centrifugation supernatant from step 3 into the column, cap the tube, and centrifuge at 12,000 rpm for 30-60 s.

5. Discard the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, add 500 ul of Buffer WA to the column, cap the tube, and centrifuge at 12,000 rpm for 30-60 s. *Confirm that the ONA is released in the column. -Make sure that anhydrous ethanol has been added to the Buffer WA.

6. Discard the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, add 600 ul of Buffer WB to the column, cap the tube, and centrifuge at 12000 rpm for 30-60 s. *Confirm that anhydrous ethanol has been added to Buffer WA.

Confirm that anhydrous ethanol has been added to the Buffer WB.

7. Dispose of the filtrate from the 2 ml centrifuge tube, return the column to the 2 ml centrifuge tube, cap the tube and centrifuge at 12000 rpm for 2 min.

*If the centrifuge cannot reach 14000 rpm, centrifuge at the highest speed for 2 min.

*Do not omit this step, otherwise the purified nucleic acid may be mixed with ethanol, which may affect the subsequent experimental results.

8. Discard the 2ml centrifuge tube, put the nucleic acid purification column into a clean 1.5ml centrifuge tube, blow the fan for 5min, add 100~200p165℃ preheated Buffer TE into the purification column, cover the tube, let it stand at room temperature for 2min, and then centrifuge at 12000 rpm for 30s.

9. Discard the purification column, the eluted DNA can be used immediately for various molecular biology experiments; or store the DNA at -20'℃ for backup.

How Much Does a Centrifuge Cost?

It wouldn’t be right to mention one fixed amount.

The centrifuge price will vary from model to model.

To know the exact price, you can ask your preferred manufacturer to provide a quotation for the type of centrifuge you want.

How Many Rpm/Fast Does a Centrifuge Spin?

Centrifugal separation equipment typically operate at speeds between 100 - 100,000 rpm:

Low-speed centrifuges: speeds usually less than 10,000 rpm, suitable for separating larger cells, bacteria or precipitating insoluble matter.

High speed centrifuges: speeds between 10,000 - 30,000 rpm, suitable for separating biological macromolecules such as organelles and viruses.

Ultra-high speed centrifuges: speeds greater than 30,000 rpm, used for ultra-fast centrifugation, such as protein purification and nucleic acid extraction.

How To Clean a Centrifuge?

In the inner chamber of the centrifuge, several cleaning heads or cleaning tubes are set up, and the centrifuge can be cleaned inside the centrifuge without opening the cover or during operation.

Focus on the following parts:

1) Cleaning of the bottom surface of the drum and the bearing seat parts;

2) Surface of the liquid stopper plate and the outer surface of the drum cylinder;

3) Inner surface of the drum cylinder;

4) Inner surface of the flip cover and the surface of the feeding, scraper and other devices;

5) Inner surface of the shell.

Common problems and solutions of centrifuges.

Centrifuge tube sample leveling problems, if the sample is not balanced, it will lead to electrode shaft bending over time, affecting the life of the centrifuge.

After an emergency power failure during operation, the door cover can be opened from the emergency hole on the side of the device to remove the sample.

If the equipment cannot be started after a power failure, the circuit board may be faulty, or the fuse at the power supply may be burnt.

If the machine fails to start normally, the door cover may not be tight, and the display will indicate a system failure.

How To Maintain a Centrifuge?

I. Daily cleaning and inspection

1. After each use of the centrifuge, the dirt and residue inside and outside the centrifugal chamber should be cleaned in time to avoid corrosion of the equipment or affect the centrifugal effect.

2. Regularly check whether the centrifuge power cord, plug and socket is intact, no damage, aging phenomenon, to ensure electrical safety.

3. Observe whether there is abnormal sound, vibration or odor during the operation of the centrifuge, if any, should be stopped in time for inspection.

Second, regularly check the lubrication system

1. Regularly check the centrifuge bearings, transmission gears and other lubrication parts to ensure that the lubricating grease is sufficient and clean.

2. According to the requirements of the equipment manual, regular replacement or supplementation of lubricating grease to ensure smooth and stable operation of the equipment.

Third, the motor and belt maintenance

1. Regularly check the running condition of the motor, including temperature, noise, etc., if there is any abnormality, it should be dealt with in time.

2. The motor belt should be kept at a proper tension to avoid loose or too tight resulting in reduced transmission efficiency or belt wear.

Fourth, bearing and seal maintenance

1. Regularly check the wear and tear of the bearings, if there is serious wear and tear or abnormalities should be replaced in a timely manner.

2. The seals should be checked regularly for their integrity, and should be replaced in time if they are aging or broken, in order to prove the sealing performance of the centrifuge.

V. Cleaning and maintenance after shutdown

1. After the centrifuge shutdown, its internal and external comprehensive cleaning to avoid residues on the equipment caused by corrosion.

2. Cleaning should be wiped with a soft cloth, avoid the use of corrosive cleaning agents or tools.

Sixth, maintenance and maintenance records

1. The establishment of centrifuge maintenance and maintenance record sheet, a detailed record of each maintenance and maintenance of time, content, replacement of parts and other information.

2. Through the record can be timely understanding of the maintenance status of the equipment, for the future maintenance and repair to provide a basis.

Seven, professional maintenance and overhaul

1. If encountering centrifuge failure or abnormal situation, should contact the professional maintenance personnel in time to deal with, do not privately disassemble or repair.

2. Regularly carry out comprehensive overhaul of the centrifuge in order to find and solve potential problems and ensure the long-term stable operation of the equipment.

What Are The Rules For Using a Centrifuge?

Before starting the centrifuge each time, the screws between the rotor and the motor shaft must be tightened.

Before centrifugation, the tube caps must be tightened.

The centrifuge tubes to be placed in the rotor must be of the same type and the weight of the tubes must be balanced.

Symmetrical placement of centrifuge tubes.

Do not open the lid until the centrifuge has come to a complete stop to prevent injury.

Why Is It Important Not To Stop The Centrifuge Abruptly?

Suddenly stopping the speed centrifuge (Abruptly stop) can have catastrophic consequences, such as equipment damage motor scrapping, destruction of samples in the centrifuge, risks to personal safety and contaminant spread.

How To Open Centrifuge Lid?

Before opening the cover, wait for the rotor to come to a complete stop (tachometer zeroed) and the refrigeration model needs to be temperature balanced (to prevent condensation and icing), otherwise there will be serious consequences.

How To Buy A Centrifuge Machine China?

Importing high performance benchtop centrifuge machine from China can be difficult for those who are new to international imports.

Purchasing from a reputable manufacturer and supplier eliminates hassle of logistics, as they handle the safe and reliable delivery of the product directly to your place.

When buying the pharma centrifuges, it is important to keep the following points in mind:

1. Confirm that your selected supplier can securely export and deliver the machine, and ensure that your agreement includes all essential shipping information.

2. Choose the delivery way (by sea, air, or express) based on your preference.

3. Remember to factor in duty imports and taxes when calculating the total cost.

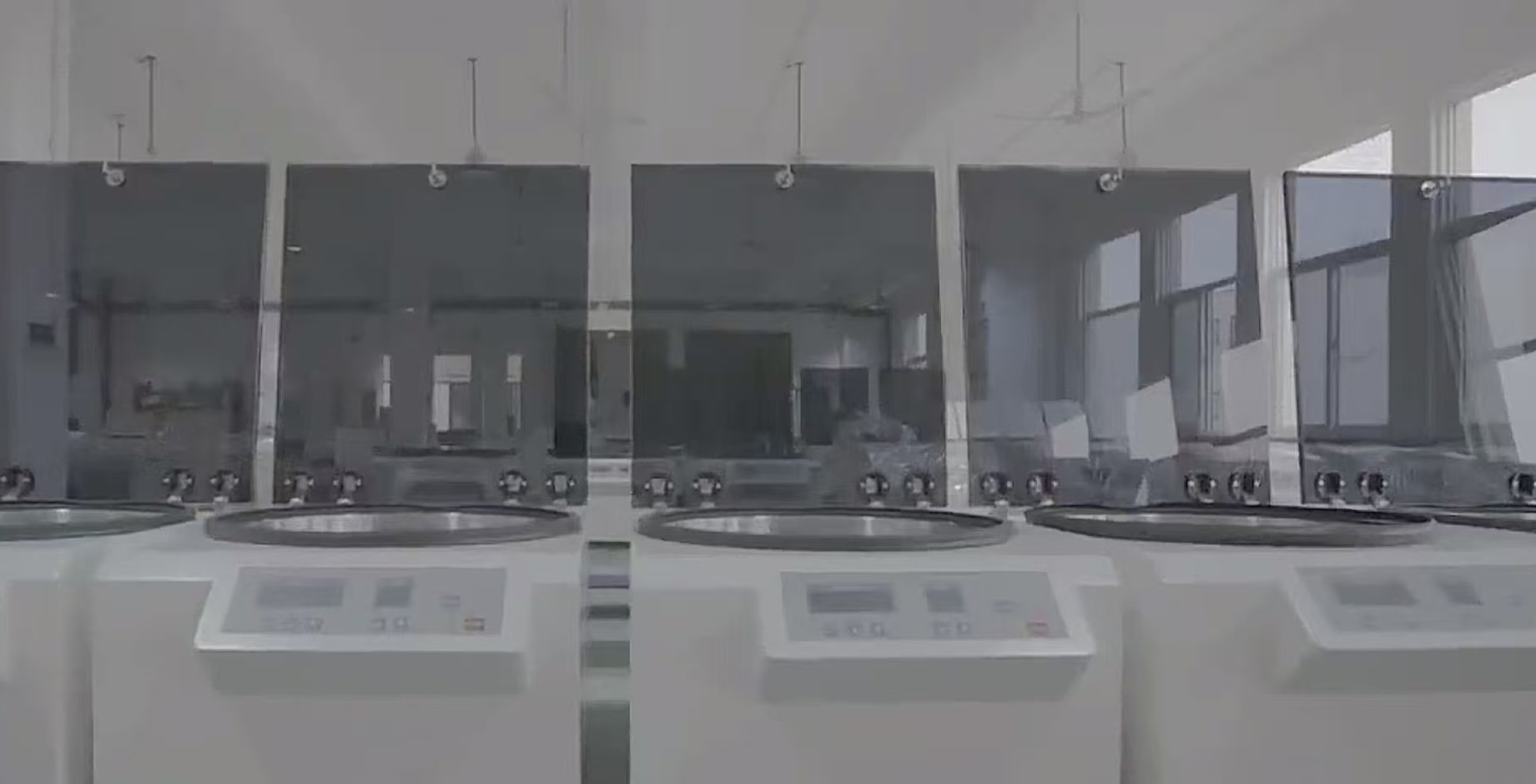

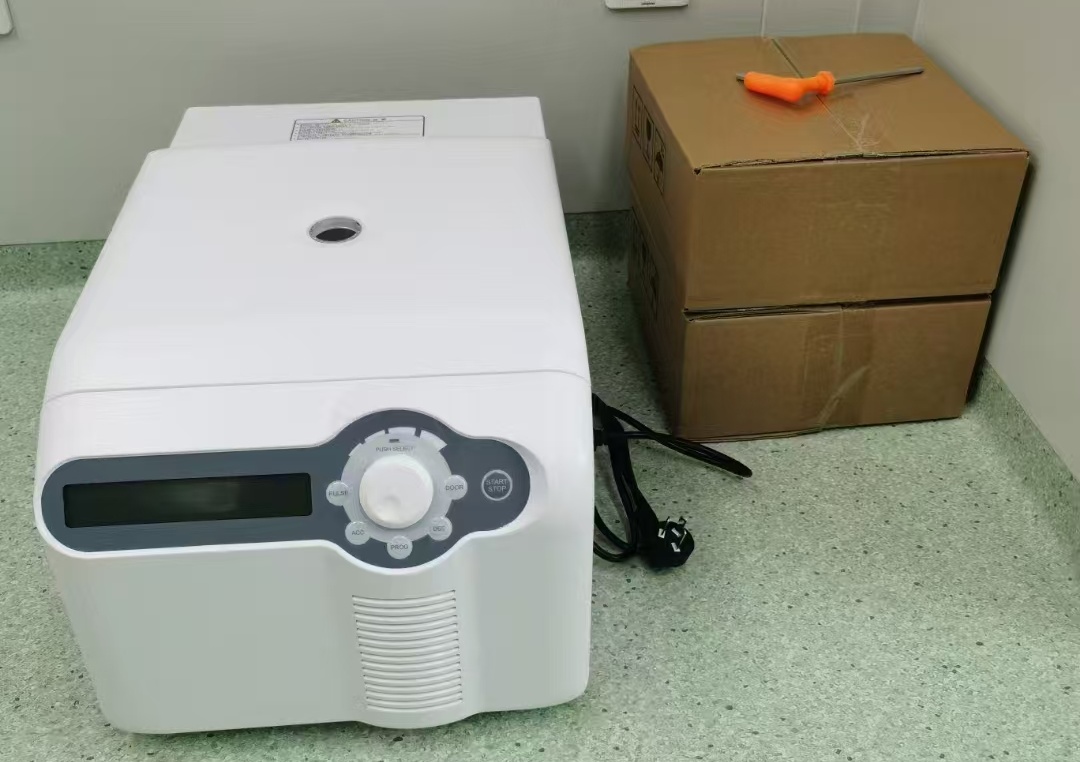

How Does a Manufacturer Deliver The Centrifuge Machine?

Safe shipping is so important as quality manufacturing.

A responsible manufacturer should deliver your centrifuge laboratory safely.

Most centrifuge manufacturers use export cartoon case to pack the device.

You should read all the necessary instructions available on the sides of the boxes before boxing.

Is There Any Warranty On Centrifuge Machine?

For optimal performance, it is important to regularly maintain your micro centrifuge, so it can operate efficiently for an extended period. It is essential to be aware of the warranty coverage for your equipment, as it ensures that any manufacturing issues will be repaired at no additional cost by the supplier. Therefore, it is recommended to purchase a prp centrifuge from a manufacturer that offers warranty services —Cialan.

Reputable prp centrifuge machine manufacturers typically provide a 1-year warranty. for example, offers complimentary repair and maintenance services during the first year.

Before purchasing a platelet rich plasma centrifuge, it is advisable to review the warranty period and other associated terms and conditions.

What After-Sale Service Does A Centrifuge Machine?

The reliable china centrifuge machine suppliers offers the following after-sale services:

1. Secure product delivery.

2. Thorough inspection prior to installation.

3. Complimentary online guidance for device installation and maintenance.

4. Free training for your users.

5. Regular assessments of your cell centrifuge.

Can You Do OEM&ODM For Centrifuge Machine?

Yes, Cialan can do OEM#OEM for our users, just send us your requirements for bench centrifuge.

Where To Find Centrifuge Machine Manufacturers?

Numerous online directories can connect you with pharmacy grade refrigerator manufacturers.

A simple search for "top-rated centrifuge for laboratory manufacturers" yields multiple options. However, it's essential to exercise caution when selecting a manufacturer from online search results. Before making a decision, conduct thorough research on the company's background and reputation. Look up reviews on “Google” and reputable review sites to gauge their credibility.

Additionally, It's also crucial to review their portfolio of request that potential manufacturers share examples of their previous work to ensure they meet your standards.

How To Choose A Right Centrifuge Machine?

Horizontal centrifuges need to be purchased with attention to factors such as speed, temperature, capacity, rotor, control system and motor. The rotational speed should be determined according to the quality of the sample and the type of rotor, the temperature should be selected according to the nature of the sample, and the capacity should match the workload.

Rotor selection should be based on separation purpose and sample characteristics, control system should be user-friendly and safety and security features, and motor should be selected as carbon brushless motor to reduce pollution and noise. In addition, noise and accessories should also be considered.

What Should You Look For In The Best Centrifuge Machine?

The best centrifuge has efficient control of speed and temperature to ensure rotor safety, low vibration and noise, long service life and low maintenance cost.